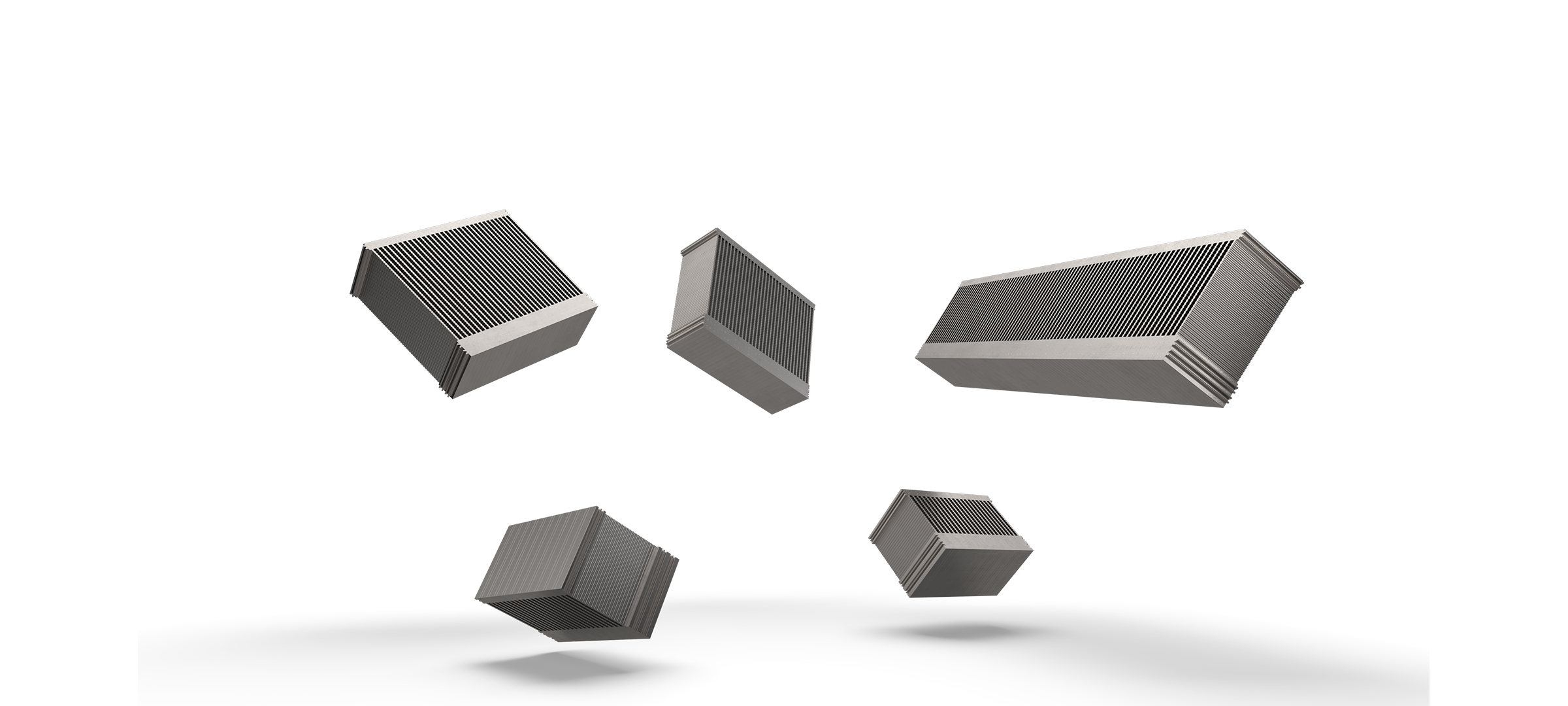

Precision Heat Sinks forMaximum Power Densities

FlexFin Skiving & ThermoFlex: When standard geometries reach their limits. High-precision manufacturing from a single piece for extreme thermal requirements. Made in Germany.

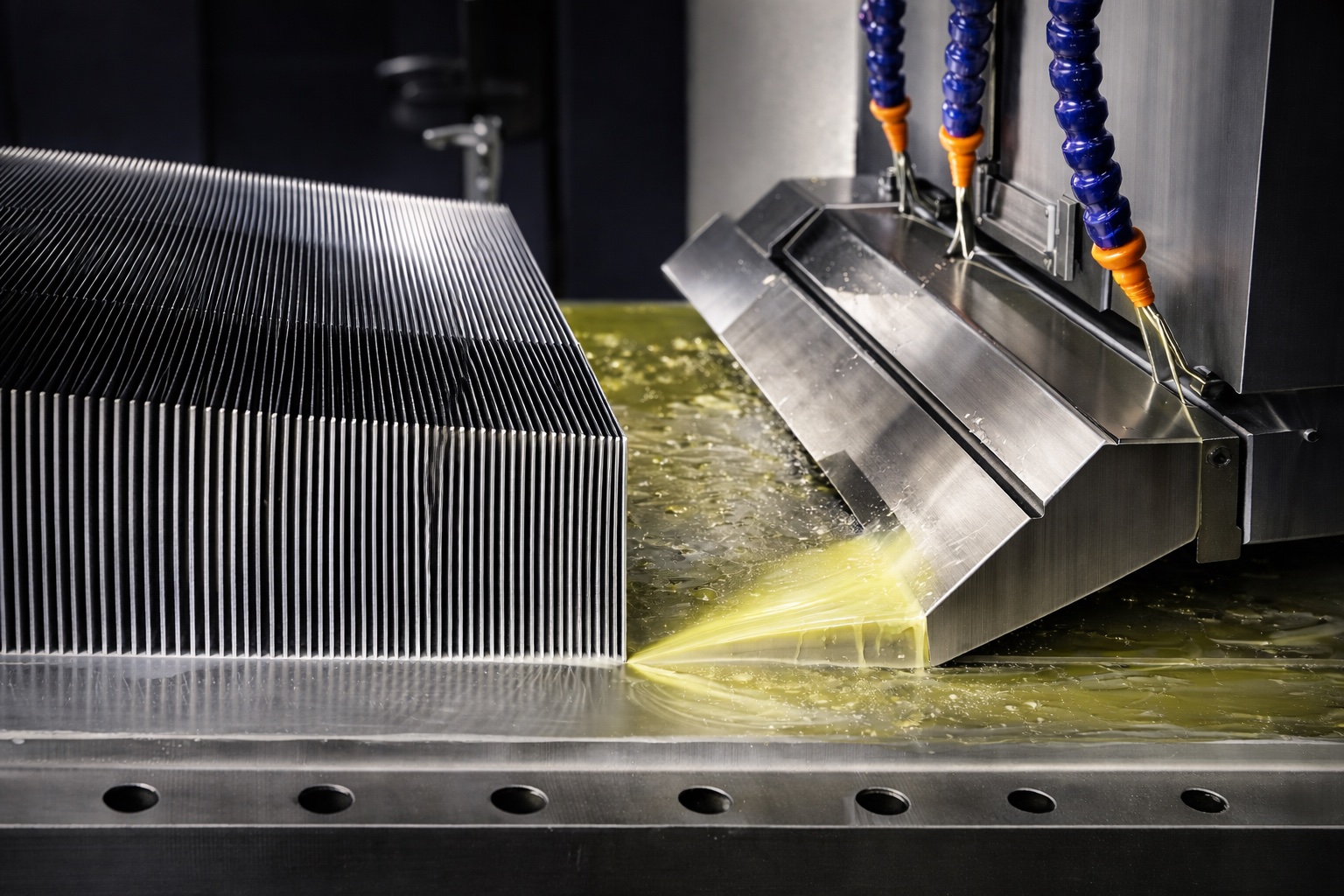

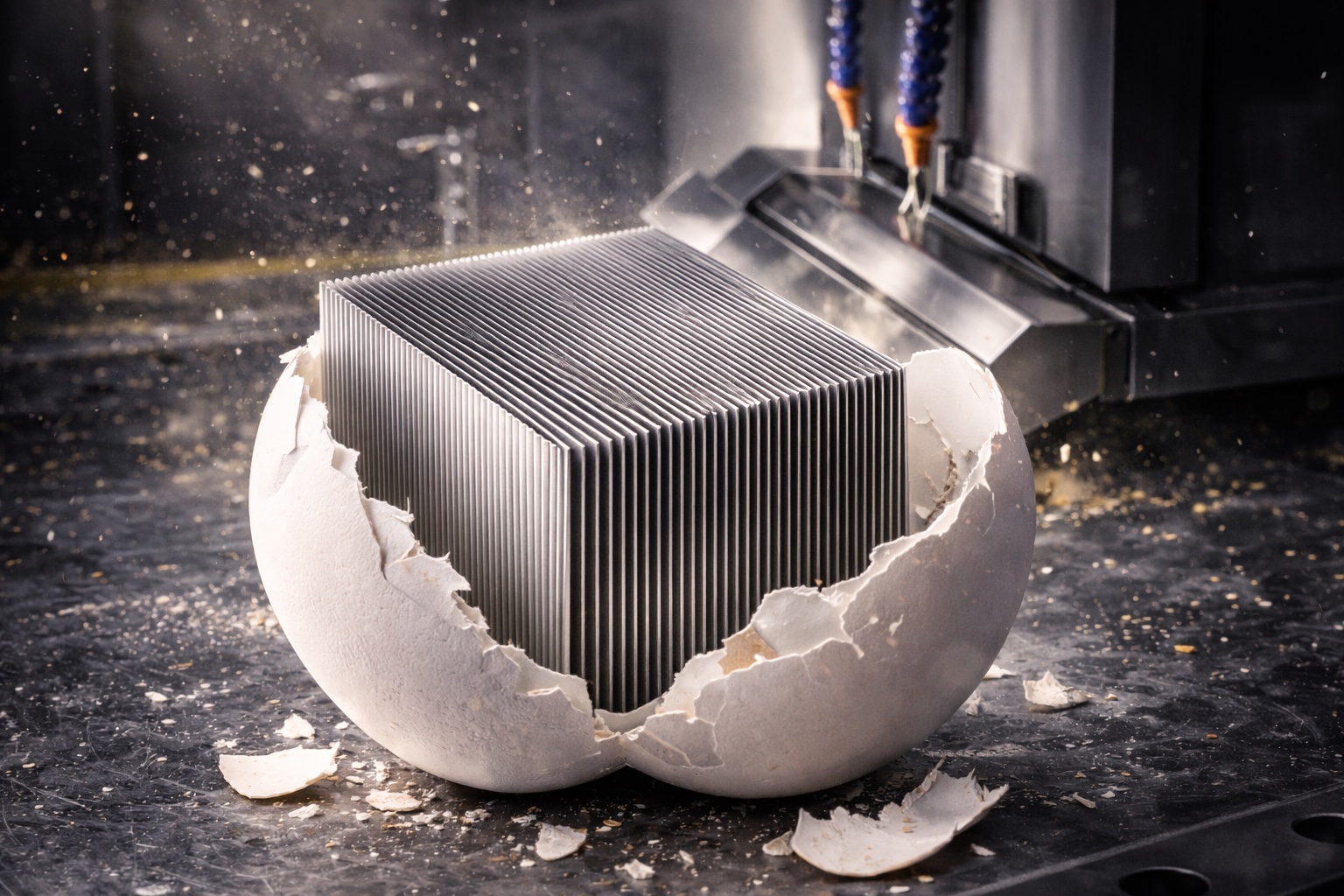

Precision in Action

Experience the manufacturing of our high-performance heat sinks. Made in Germany.

Two Technologies for Highest Requirements

FlexFin Skiving for maximum power density. ThermoFlex for flexible high-performance heat sinks through innovative press technology.

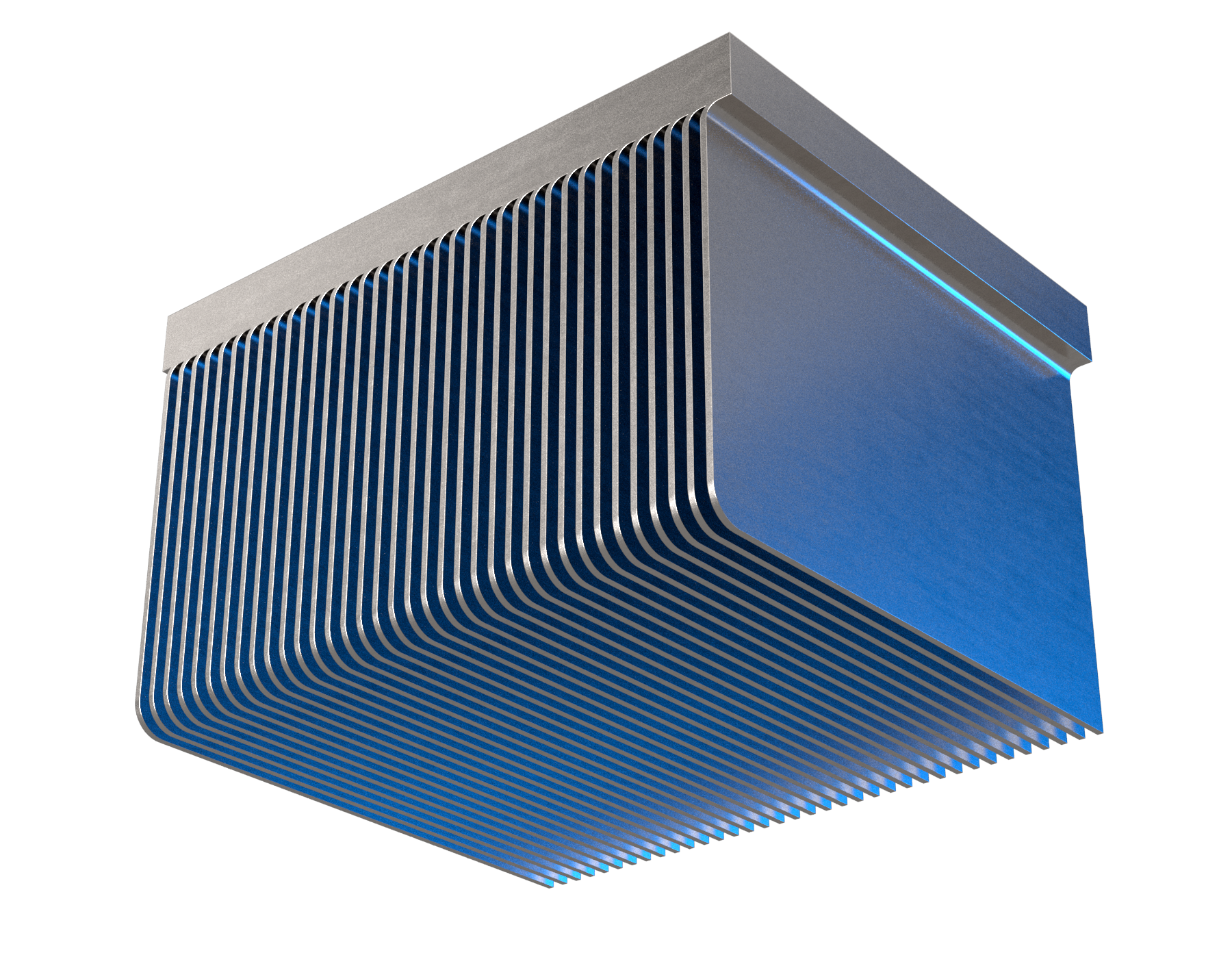

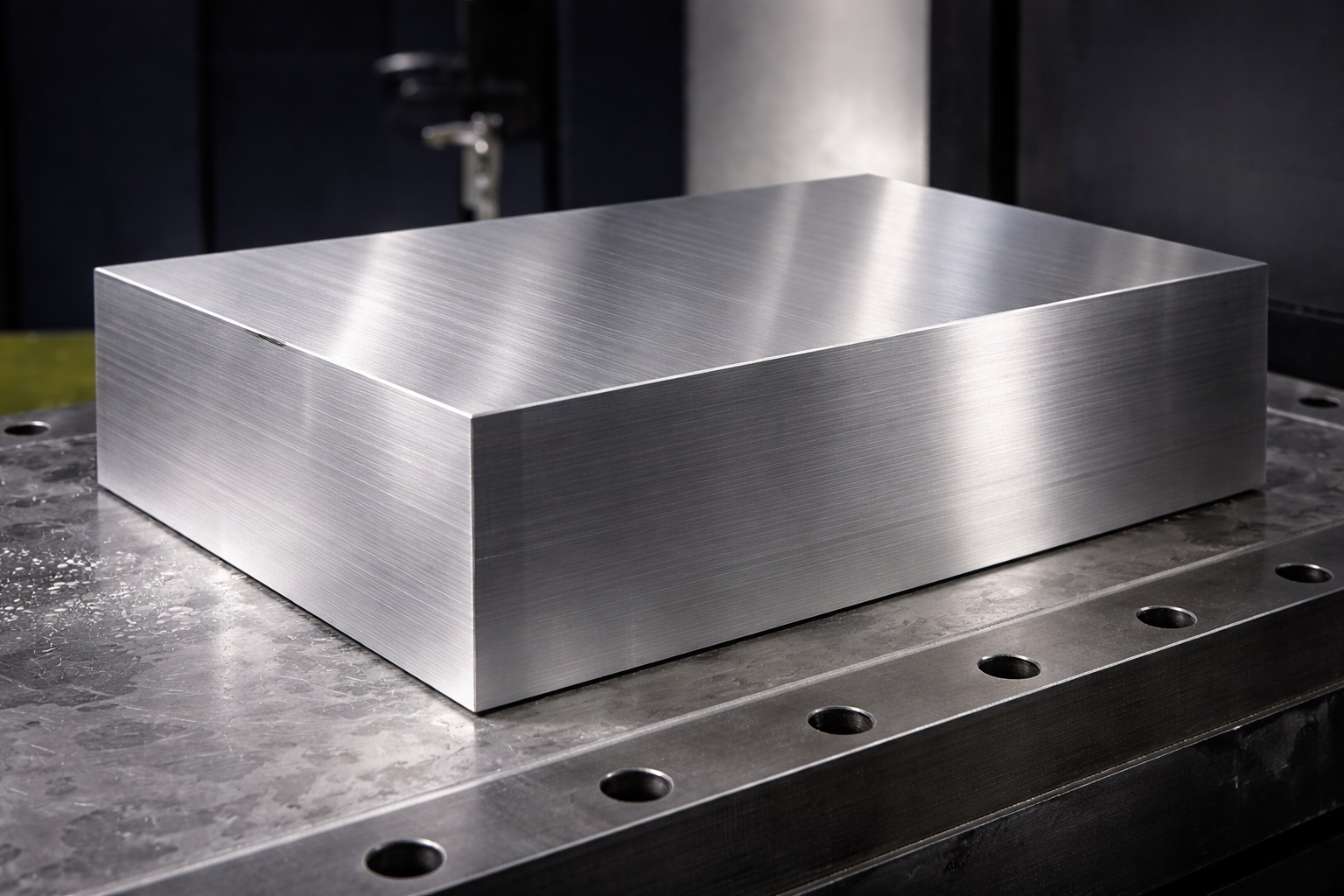

FlexFin Skiving

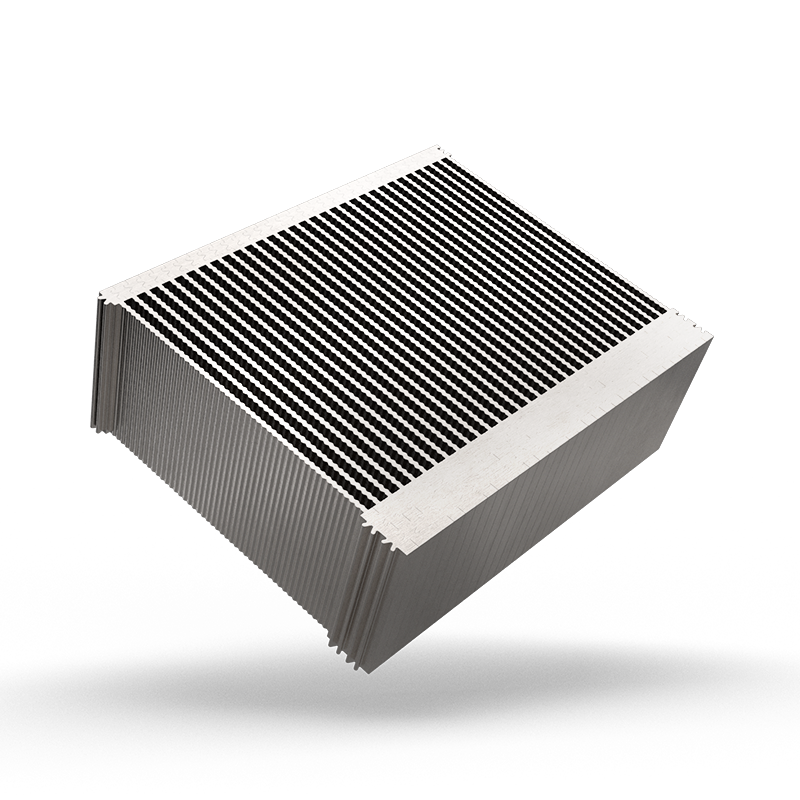

Precision Heat Sinks for Maximum Power Densities

High-precision skiving manufacturing from a solid aluminum block. Extremely high fin density, minimal thermal transition resistances and maximum design freedom.

ThermoFlex

Flexible High-Performance Heat Sinks through Innovative Press Technology

New press technology with optimized base material that significantly exceeds classic extrusion profiles. Combines high design freedom, economical manufacturing and excellent thermal properties.

50+ Years Engineering Guarantee

Precision Heat Sinks for Maximum Power Densities

In the skiving process, we apply a special manufacturing technique where finned heat sinks are 'peeled' from a single piece. The individual heat sink fins are directly connected to the base without any transition. The base and fins of FlexFin Skiving heat sinks form a thermal unit.

Basis und Lamellen bilden eine perfekte thermische Verbindung ohne Übergangswiderstand.

Höchste mechanische Stabilität und Zuverlässigkeit durch monolithische Fertigung.

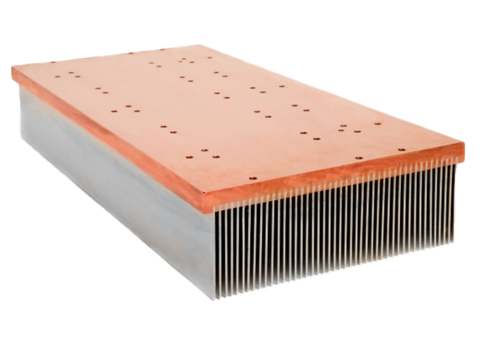

The fins are machined from an aluminum block of the 1.000 series or the 6.000 series. Aluminum's thermal conductivity is optimal at up to 230 W/mK. If higher heat dissipation performance is required, copper (Cu1100) can also be used as the base material.

The compact design from a single piece makes the heat sinks less susceptible, as no additional material is used to connect the base plate to the individual fins. With the same surface area, the heat sink is lighter and saves material costs.

There is no thermal interface resistance, as exists in heat sinks with pressed, soldered or glued fins. Thoughts about loosening fins or aging joining material are thus unnecessary. FlexFin Skiving heat sinks from Seifert electronic GmbH are excellently suited for thermoelectric applications or power modules with high power loss.

We manufacture FlexFin Skiving heat sinks exactly according to customer-specific requirements and are maximally flexible. We don't negotiate on one thing: Every single FlexFin Skiving heat sink is perfectly finished.

Manufactured exactly to your customer-specific requirements.

Every single heat sink is finished flawlessly.

Technical Parameters

Precisely specified for maximum performance

Why FlexFin Skiving?

manufacturing from one piece

geometry and design freedom in heat sink dimensions

No tooling costs – enables small series

Fast prototypes without tooling investment

Experience the quality in person – let us solve your thermal challenge.

Heat Sink InquiryThermal Solutions for Every Industry

From railways to renewables. From defense to e-mobility. Precision cooling where it matters most.

Railway Technology

Reliable thermal solutions for traction converters, braking systems, and onboard electronics.

Wind Energy

High-reliability cooling for wind turbine converters and generators in harsh environments.

Defense & Aerospace

MIL-spec thermal management for mission-critical military and aerospace applications.

LED Technology

Precision thermal management extending LED lifetime and maintaining light quality.

Laser Systems

Ultra-precise cooling for industrial laser systems requiring tight temperature control.

Power Electronics

Advanced cooling for high-density power conversion and motor drive systems.

Medical Technology

Medical-grade thermal solutions for diagnostic and therapeutic equipment.

E-Mobility

Next-generation cooling for electric vehicle powertrains and charging infrastructure.

Mercosur

Certified thermal solutions for the Mercosur market. Compliance with regional regulations and international quality standards.

Your industry not listed? We engineer custom thermal solutions for any application.

Discuss Your Requirements

Engineering Perfection

FlexFin Skiving & ThermoFlex: High-precision manufacturing technologies for maximum thermal performance. Engineered for extreme power densities.

Thermo Simulation

CFD analysis and thermal modeling for optimized FlexFin Skiving & ThermoFlex design. Calculation of optimal fin geometry and heat distribution before production.

Material Science

Aluminum alloys optimized for FlexFin Skiving & ThermoFlex. Maximum thermal conductivity (λ > 200 W/mK) and mechanical strength for monolithic and pressed structures.

Testing & Validation

In-house thermal testing laboratory for validation of FlexFin Skiving & ThermoFlex performance. Ensuring specifications for Rth, fin density and mechanical stability.

Made in Germany

50+ years manufacturing excellence for FlexFin Skiving & ThermoFlex. Certified quality management systems for precision skiving and innovative press technology.

Engineering Process

From concept to delivery: Your FlexFin or ThermoFlex solution in 5 steps.

Requirements Analysis

Detailed specification of thermal, mechanical, and environmental requirements. Decision between FlexFin Skiving (maximum power density) or ThermoFlex (flexible press technology).

Thermal Simulation

CFD analysis and thermal modeling to optimize FlexFin Skiving or ThermoFlex geometry. Calculation of optimal fin density, spacing and height.

Design & Engineering

CAD design for FlexFin Skiving (monolithic structure) or ThermoFlex (press technology). Material selection and manufacturing constraints for both technologies.

Prototyping & Testing

Rapid prototyping without tooling costs for FlexFin Skiving & ThermoFlex. Thermal validation in our test lab with measurement of Rth and performance.

Production & Delivery

Series production of FlexFin Skiving (skiving manufacturing) or ThermoFlex (press technology) with continuous quality control. Economical even for small series.

Let's Discuss Your Project

We look forward to your inquiry and are happy to advise you on your thermal challenge.

Your Contacts

Christoph Schumacher

Sales Director D-A-CH

Rikard Buråker

European Sales Director